Shop Top-Quality RFID Labels

Explore High-Performance RFID Labels

Where can RFID-labels be used?

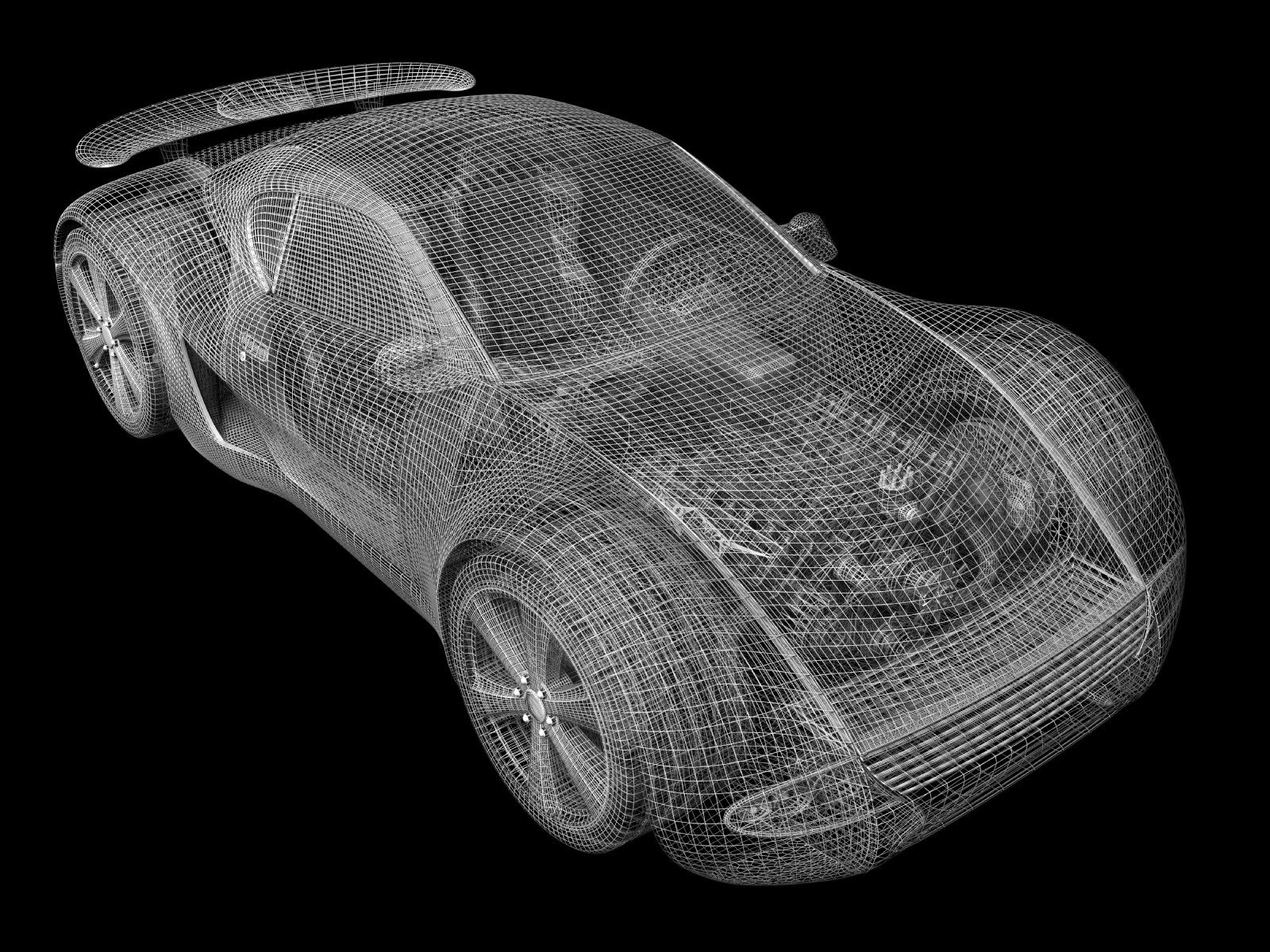

Nowadays, RFID systems are predominantly used in the logistics and retail sectors. A variety of application options can also be found in production, in goods and inventory management, in vehicle identification, in the fight against product piracy, and many more areas.

Consumers frequently encounter RFID technology in the realm of contactless payment systems. The use of RFID transponders is also well established in working hours recording and electronic locking systems. Integrated in identity cards and passports, RFID chips are also used for personal identification.

APPLICATIONS

Material composition of RFID-labels

Depending on the application, RFID labels can be produced in a completely customized and individual manner, both with regard to the label characteristics and the RFID chip.

Outer material

The selection of outer material used for RFID-labels ranges from thermal printing paper or thermal-coated paper through to various types of film (PE, PP, PET).

Adhesive

There are also a wide range of options available when it comes to the adhesive used in RFID-labels as it is particularly important. You can select between adhesives which are particularly temperature-resistant and suitable for use in the food industry, and those that are resistant to chemicals or can be easily removed.

RFID inlay

The RFID chip and antenna can also be individually modified to suit customer requirements. When it comes to the RFID chip, attention must be paid to the different memory sizes and reading attributes. The reading range is also influenced by the size and surface area of the antenna.

What sizes can RFID-labels be?

The adhesive labels can either be created in a variety of standard sizes or order-based in almost any requested label format.

How are RFID-labels delivered?

RFID labels can be manufactured either already printed or suitable for self-printing.

RFID labels solutions from PMG Labels

As a specialist supplier of high-quality RFID-labels, we develop, produce and test RFID-labels for every field of application. You are provided with an extensive, continually expanded portfolio of RFID labels for every application.

Why RFID-labels from PMG?

Development

We employ our great professional expertise to develop your customized product solution to entirely meet your requirements.

Production

During production we leave nothing to chance. We rely on the most modern machinery and to guarantee the utmost precision in each individual label.

Quality

We place importance on the use of highly modern camera monitoring systems for our quality control and thus guarantee the highest level of quality through our 100 % final inspection.

Reliability

You can always rely on the extensive know-how and advisory skills of our staff. We accompany you at all times with expertise and flexibility, from the first point of contact right through to the final execution of your project and beyond.

Your advantages with RFID-labels

Unlike conventional barcode labeling, RFID labels are rewritable and no visual contact is required for radio contact. Thus, it is no longer necessary to establish direct contact between the transmitter and receiver. Depending on the type of RFID transponder, reading ranges of a few centimeters to 20 meters can be achieved. In addition, the radio can easily penetrate many types of materials. Because the shape and size of the transponder can be adapted to all conditions, the RFID chip can even be integrated into the packaging or completely into the respective product. In addition, the microchip is resistant to environmental influences and the information and data can still be read without any problems even if it is extremely dirty.

Numerous advantages with RFID for logistics industry

The identification of the goods takes place within a few seconds and about 20 times faster than by means of barcode. In this way, workflows can be simplified, accelerated and thus costs can be saved considerably, as well as the efficiency and profitability of a company can be increased many times over.

No visual contact or direct contact necessary

Insensitivity to contamination

Identification of goods within the shortest possible time

Simplified accelerated processes lead to cost savings

Your challenges without RFID

Manual data collection

Without RFID, data collection must be done manually, which can be time-consuming and error-prone.

No individual identification or localization of goods

While barcode labels provide some inventory tracking, it is not as accurate or comprehensive as RFID labels. This can lead to out-of-stocks or lost products.

Lack of transparency regarding the condition and history of components and materials

Lower efficiency in the management of goods and inventory.

Higher costs

Manual data entry and limited inventory tracking can lead to higher costs, as more staff is needed and there may be increased errors that incur costs.

Do you have any questions?

Are you unsure as to how RFID can improve your business, your supply chain or your production processes? Or do you have any other questions regarding RFID Labels?

Feel free to contact us! Our label Experts with extensive knowledge are on hand for non-binding discussions and can be contacted by e-mail at info@pmglabels.com.

We are continually adding to our product portfolio and are developing and producing the most modern RFID labels for the most varied of industries and applications, from inexpensive, standardized labels through to your own entirely individual, customized product solution.

We will be happy to personally advise you about our advantages and wide-ranging benefits for your company.